How Automatic Unscramblers Enhance Consistency in Bottle Orientation

In modern packaging environments, maintaining uniform orientation of containers is essential for smooth downstream operations. Filling, capping, labeling, and inspection processes all depend on bottles arriving in a predictable position. When containers are misaligned or inconsi…

Integrating Automatic High Speed Bottle Unscramblers Into Automated Lines

Modern packaging operations depend heavily on speed, consistency, and minimal manual intervention. As production volumes grow and product variations increase, manufacturers are under pressure to ensure smooth material flow from the very first stage of the line. One critical elem…

How Bottle Unscramblers Reduce Downtime in Packaging Operations

Downtime is one of the most costly challenges in packaging operations. Even brief interruptions can disrupt production schedules, increase labor costs, and delay order fulfillment. In high-volume environments where containers must be fed consistently into filling and labeling li…

Smart Technology in Bottle Unscrambling: Innovation in Packaging Automation

Packaging lines in today’s manufacturing units are rapidly evolving with the help of smarter, faster, and more accurate automation systems. One area that has undergone noticeable transformation is the bottle feeding process, where consistent orientation, high efficiency, and min…

Packaging Automation for Food Industries: The Power of Bottle Unscramblers

In the modern food industry, efficiency, precision, and hygiene are key pillars that define successful production. As consumer demand grows and product variety expands, companies are constantly looking for ways to streamline their packaging processes. One of the most innovative …

Benefits of using an Automatic High Speed Bottle Unscrambler

An automatic high speed bottle unscrambler offers several benefits to the packaging and manufacturing industry by streamlining the bottle handling process and improving production efficiency. Here are some key benefits of using an automatic high-speed bottle unscrambler: Increa…

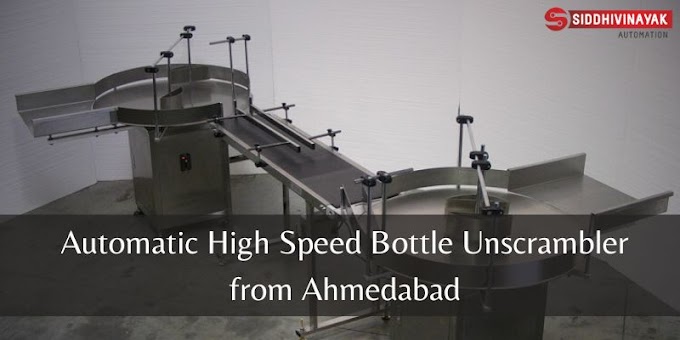

Automatic High Speed Bottle Unscrambler from Ahmedabad

An automatic high speed bottle unscrambler is a machine used in the packaging industry to efficiently sort and orient bottles or containers for further processing. Its primary function is to take a random supply of bottles and arrange them in an organized and consistent manner,…

About us

Popular Posts

Maintenance Practices That Support Reliable Shrink Sleeve Application

Search This Blog

Blog Archive

- May 20254

- April 20252

- March 20253

- February 20252

- January 20251

- December 20243

- November 20242

- October 20242

- September 20243

- August 20243

- July 20242

- June 20242

- February 20241

- January 20243

- December 20234

- October 20231

- September 20232

- August 20234

- July 20235

- June 20231

- May 20232

- April 20232

- March 20233

- February 20232

- August 20221

- June 20222

- May 20221

- April 20221

- March 20222

- December 20212

- September 20212

- July 20211

- June 20212

- May 20211

- April 20212

- March 20211

- February 20212

- January 20211

- December 20201

- November 20201

- September 20202

- August 20203

- July 20201

- June 20202

- May 20201

- April 20201

- March 20201

- February 20201

- January 20202

- December 20192

- November 20191

- October 20192

- August 20192

- July 20192

- June 20193

Labels

- Automatic Label Applicator

- automatic bottle capping machine

- Automatic Bottle Capping Machine Manufacturer

- Automatic Bottle Capping Machine Manufacturers

- automatic bottle filling and capping machine

- Automatic Bottle Filling Machine

- Automatic Bottle Filling Machine Manufacturers

- Automatic Cosmetic Filling Machine

- automatic double side sticker labeling machine

- Automatic Double-Side Sticker Labelling Machine

- Automatic High Speed Bottle Unscrambler

- Automatic Label Applicator

- Automatic Label Applicator For Bottles

- Automatic Label Applicator India

- Automatic Label Applicator Machine

- Automatic Label Applicator Manufacturer

- Automatic label applicator manufacturers

- Automatic label applicator price in india

- automatic rinsing filling capping machine

- Automatic-Bottle-Filling-Machine

- Automatic-Bottle-Filling-Machine-Ahmedabad

- Automatic-Bottle-Filling-Machine-Manufacturers

- Automatic-Bottle-Filling-Prices

- Automatic-Label-Applicator

- Automatic-Label-Applicator-Machine

- Automatic-Label-Applicator-Manufacturers

- Automatic-Label-Applicator-Prices

- Automatic-Label-Applicator-Supplier

- Automatic-Shrink-Wrapping-Machine

- Benefits for Automatic Label Applicator

- Benefits-Shrink-Wrapping-Machine

- bottle capping machine price in india

- Bottle Filling Machine

- bottle sticker labeling machine

- Bottle-Sticker-Labeling-Machine

- Double Side (Front & Back) Labeling Machines Manufacturers

- Double Side Sticker Labeling Machine

- double side sticker labeling machine manufacturer

- Double-Side-Sticker-Labeling-Machine

- Double-Side-Sticker-Labeling-Machine-Prices

- hologram labeling machine

- Hologram-Labeling-Machine

- Hologram-Labeling-Machine-Manufacturer

- Hologram-Labeling-Machine-Prices

- How-to-Shrink-Wrap-Bottles

- Importance-of-Shrink-Wrapping-Machine

- Jar Filling Machine

- Label Applicator

- Label Applicator Machine

- Labeling-Machines

- Labeling-Machines-Manufacturers

- Packaging-Equipment-and-Machines

- Pet Bottle Filling Machine

- semi automatic bottle capping machine

- Semi Automatic Bottle Filling Machine

- Semi Automatic Label Applicator

- Shrink Sleeve Applicator Machine

- Shrink Sleeve Applicators Machine

- Shrink Sleeve Applicators Machine Manufacturer

- Shrink Tunnel Machine Cost

- Shrink Tunnel Machine Manufacturer

- Shrink Tunnel Machine Manufacturer in India

- Shrink Tunnel Machine Manufacturers

- Shrink Tunnel Machine Manufacturers India

- Shrink Tunnel Machine Supplier In India

- Shrink Tunnel Machines

- Shrink Tunnel Manufacturers

- Shrink Wrap Machine

- Shrink Wrapping Machine

- Shrink Wrapping Machine Cost

- Shrink Wrapping Machine Manufacturer

- Shrink Wrapping Machine Price

- Shrink Wrapping Machines India

- Shrink-Tunnel-Machine

- Shrink-Tunnel-Machine-Ahmedabad

- Shrink-Tunnel-Machine-Manufacturers

- Shrink-Tunnel-Machine-Price

- Shrink-Wrapping

- Shrink-Wrapping-equipment

- Shrink-Wrapping-Machine

- Shrink-Wrapping-Machine-Manufacturer

- Shrink-Wrapping-Machine-Manufacturer-in-Ahmedabad

- Shrink-Wrapping-Machine-Prices

- Shrink-Wrapping-Machine-Supplier

- Single Side Sticker Labeling Machine

- Sticker Labeling Machine

- Sticker Labeling Machine Manufacturers

- Sticker Labeling Machine Manufacturers in Ahmedabad

- Sticker-Labeling-Machine

- Sticker-Labeling-Machine -Prices

- Sticker-Labeling-Machine-in-Ahmedabad

- Sticker-Labeling-Machine-Manufacturers

- Sticker-Labeling-Machine-Manufacturers-in-Ahmedabad

- Sticker-Labeling-Machine-Manufacturers-in-India

- Sticker-Labeling-Machine-Prices

- Stretch Wrapping Machine

- Wrapping-Machine

Contact Form

- Siddhivinayak Automation

-

Siddhivinayak Automation is one of the leading manufacturer, exporter and supplier of high quality packaging machinery